Compression Limiters are designed to protect the plastic components of an assembly from the compressive loads generated by the tightening of bolts thereby assuring continued integrity of the bolted connection. Danielson CT SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies.

Tr Launches Range Of Compression Limiters Fastener Fixing Magazine

2 SPIROLs 5 Step Process for Success When you engage SPIROL as part of your team we will utilize our.

. The second design adds a soft-knee threshold. Suggestions for alignment are presented as are ideas for modifying the basic cir-cuits to allow common variations. They protect plastic parts from damage due to compression by limiting the force that gets applied to the plastic by the assembly fasteners.

DIN EN 16983 formerly DIN 2093 Stainless Steel. Made from brass these inserts are nonmagnetic mildly corrosion resistant and electrically conductive. 1 COMPRESSION LIMITERS π x Ø2 2 - Ø1 2 ØA ØC ØB L 2.

Design guidelines for Compression Limiters to avoid the risk of exceeding the elastic limit of the plastic component. Vogelsang offers an extensive line of cost saving compression limiters. Metric Nuts and Washers.

Included are the specifications for their standard split seam molded-in and solid wall designs as well as their brand new oval series. Threaded Insert Installation. The first design is an above-threshold hard-knee compressor with variable ratio thresh-old and gain controls.

Compression is heralded as one of the holy grails of mixing any sort of electronic music. Hole Design Although the split seam Compression Limiters have a broken edge. Innovation today for a better tomorrow growing sustainably together.

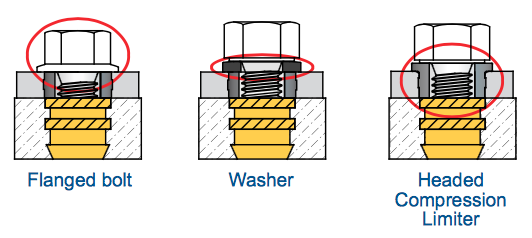

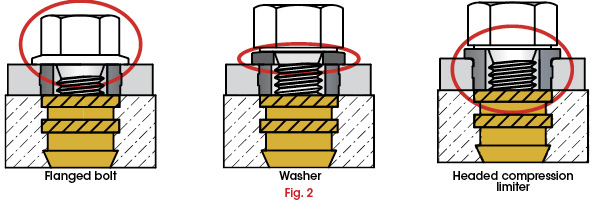

Compression limiters are designed for applications where the. Headed Compression Limiters are only available as solid components because of the tolerances required for proper Compression Limiter operation. 15099 CDN EuropeUK MSRP Price.

Addressing these design issues prior to requesting quotes will insure you are using the most cost effective Limiter for your application. Ultrasonic insertionCompression limiters are placed into a molded or drilled hole that is slightly smaller than the diameter of the insert. Compression limiters are a type of insert or bushing designed to maintain joint integrity of a plastic assembly when tightening bolts or screws.

If the compression. The primary function of a Compression Limiter is to provide and maintain joint integrity. The primary function of a.

In practice the Compression Limiter should be slightly shorter than the thickness of the plastic host. For example an ISO 109 grade fastener will require a Compression Limiter made from higher strength materials or a heavier wall cross section than an assembly using an ISO 58 grade fastener. COMPRESSION LIMITERS x 22 - 12 AP 4 B L A C 1 The Function of a Compression Limiter The primary function of a Compression Limiter is to provide and maintain joint integrity of a plastic assembly.

Download the latest SPIROL Compression Limiters Design Guide for help in selecting the best Compression Limiter for your assembly. Also known as compression limiters they keep screws securely installed even if the surrounding plastic expands or shrinks when the screw is tightened. Threaded Inserts for Plastics.

The multiple design options in our compression limiters combined with our dedicated team of engineers allows your product to incorporate the shapes materials and features you need. ProSet XT3 Blind Rivet Tool 76003 ProSet XT4 Blind Rivet Tool 76004 Hydro-Pneumatic Power Tool Accessories Instruction Manual. The compression limiter strengthens the.

For technical drawings and 3-D models click on a part number. Thereafter the Compression Limiter and plastic will compress at the same although greatly reduced rate. A compression limiters weight should be equal to or slightly less than the host component to allow for a small amount of plastic compression when the mating bolt is torqued.

Our punch press manufacturing process offers substantial cost savings over other products and allows for a wide variety of additional options. Installation of Compression Limiters can be done through various technique using heat ultrasonic mold-in or press-in. Compression limiters are made to meet your individual specifications.

1 COMPRESSION LIMITERS x 2 2 - 1 2 A C B L. The Compression Limiters length should be designed to ensure it will bottom out against the surface under the bolts head and mating component. 2 SPIROLs 5 Step Process for Success When you engage SPIROL as part of your team we will utilize our 5 Step Process for Success to ensure that you receive an accurate solution in a timely manner.

Included are the specifications for their standard split seam molded-in and solid wall designs as well as their brand new oval series. The primary function of a Compression Limiter is to provide and maintain joint integrity. 1 Design Guide Threaded Inserts For Plastics a ten point guide.

1 Prepare holes with a taper of 1. Below or download the Compression Limiters Design Guide. Plas Fix 45 Installation Guide.

SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic assemblies. Solid compression limiters provide a strong and reliable defence against the stresses caused by fastener torque. See Other Hemi Engine Spec Guides Here.

RMS compressor peak limiter high-frequency limiter clipper and true peak limiter. Screws for Plastic to JIS. Compression limiters are non-threaded bushings that strengthen the plastic and resist the applied compressive loads.

Pressorlimiter designs using these devices. The compression limiter strengthens the plastic and withstands the compressive force that is applied. Compression Limiters are designed to protect the plastic components of an assembly from the compressive loads generated by the tightening of bolts thereby assuring.

SPIROL recently released their new Compression Limiter Design Guide that provides essential design guidelines for the ideal bolted joint in plastic. The head of the bolt or washer if one is used comes into contact with the Compression Limiter.

Spirol Releases New Compression Limiter Design Guide Spirol

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Medical Design And Outsourcing

How To Ensure Bolted Joint Integrity When Using A Compression Limiter Fastener Engineering

How To Ensure Bolted Joint Integrity When Using A Compression Limiter Fastener Engineering

Compression Limiters Wisconsin Stamping And Manufacturing

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Fluid Power Journal

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly 2015 11 04 Assembly Magazine Assembly

How To Ensure Bolted Joint Integrity When Using A Compression Limiter In A Plastic Assembly Fastener Fixing Magazine

0 comments

Post a Comment